Austempered Ductile Iron Castings

We represent the best Austempered Ductile Iron foundries in the USA and back it up with professional and ongoing service.

Supplier Of The Following Austempered Ductile Iron Grades:

ASTM A48

ASTM A897-06

ADI Grade 750

1. What ASTM Grades of ADI do you source?

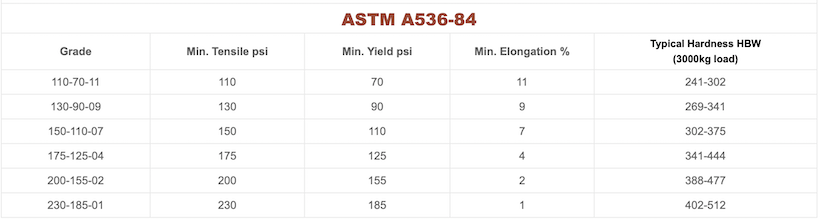

We supply all grades of ASTM A897-06 including 110-70-11, 130-90-9, 150-110-7, 175-125-04, 200-155-2 and 230-185-1 (Also known as grades 750, 1, 2, 3, 4 and 5.)

2. What range of sizes are available?

Weight ranges from a few ounces up to 5000 pounds. Dimensions up to 70” x 70”.

3. What EAU can you provide?

This is weight dependent, but as a general rule we can supply up to 50,000 pieces a year in weights up to 150 pounds. From 150 pounds to 500 pounds we can service EAUs up to 2,500 pieces. 500 pounds and up 1,000 EAU.

4. What type of molding processes do you have available?

Both greensand and no-bake. Greensand includes both semi-automatic and automatic molding lines (including Sinto, Hunter, B&P and Disa molding)

5. What type of quality control procedures do you have in place?

The majority of our partner foundries are ISO Certified. We can also offer TS Certified facilities for applications meeting certain volume and weight criteria.

6. States We Serve

- Nebraska

- Kansas

- Oklahoma

- Minnesota

- Iowa

- Missouri

- Wisconsin

- Illinois

- Indiana

- Kentucky

- Michigan

- Ohio

- Pennsylvania

- North Carolina

- Virginia

- West Virginia

ADI Specifications

ASTM A536-84

Austempered Ductile Iron castings ( ADI castings) are manufactured by heat treating ductile cast iron; small quantities of nickel, copper and molybdenum are added to enhance hardenability. ADI castings offer exceptional strength-to-weight ratios, with excellent fracture resistance and fatigue strength. ADI castings density is 10% less than steel, so they're an excellent replacement for steel forgings. Replacing steel forgings with ADI castings also saves weight. ADI castings provide great design flexibility; they offer unique combinations of noise-damping properties, high strength, and wear resistance

Markets that are heavy users of this technology include:

- Construction and Mining Equipment

- Material Handling

- AG Implement and Equipment

- Automotive

- Heavy Truck

- Railroad

Typical applications include:

- Timing Gears

- CV Joints

- Steering Knuckles

- Sprockets, Rollers, Idlers

- Suspension Housings and brackets

- Wear Plates

- Wheel Hubs

- Control Arms

- Plow Points

- Hitches

- Crankshafts

- Flanged shafts

Why Call Carson Castings for a Quote?

1. Expertise in our field - We deal strictly in the sourcing of castings and machined castings. Highly specialized in Austempered Ductile Iron.

2. Added Value - We provide raw castings or complete assemblies and everything in between (painting, heat treat and machining).

3. Tooling Options – No-bake and green sand molding. Floor, manual, squeezer, cope and drag, Hunter, Sinto and Disamatic molding processes.

4. Industry Knowledge - Our years of experience in the casting field ensure we place your work at a facility suited to your project’s unique needs.