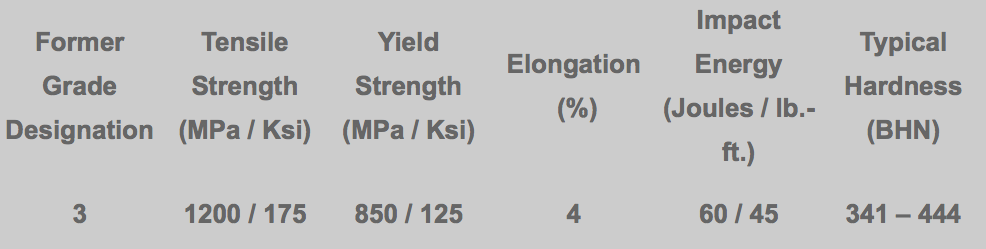

Austempered Ductile Iron ASTM A897 ADI Grade 1200 / 175 (Grade 3)

Carson Castings (Foundry-Source.com) specializes in ADI sand castings weighing 1# to 500# in flask sizes up to 48”x48”. We offer highly specialized expertise in austempered ductile iron.

We have found that austempered ductile iron (ADI) offers the best combination of low cost, design flexibility, good machinability, and a high strength-to-weight ratio as well as good durability, wear resistance and fatigue strength properties. A heat-treated form of as-cast ductile iron, ADI has found successful applications in a variety of industries including construction, mining, agriculture, automotive, railroad and heavy truck.

ASTM A897 ADI Grade 1200 / 175 is primarily utilized for applications requiring increased strength and toughness while maintaining a practical level of ductility and impact resistance. Commonly used in fabrication-to-casting conversion projects, ADI grade 3 offers mechanical performance that is often comparable to steels, without the added cost.

Some of the desirable properties of ADI Grade 3 include:

- Yield strength, toughness and impact resistance comparable to many cast/forged steels

- Vibration dampening and heat transfer superior to other ferrous/non-ferrous alloys

- Significant weight and cost savings over both aluminum and steel castings/forgings

- Increased fracture and fatigue strength

- Cost savings over aluminum and steel castings/forgings

The heat treat process, austempering, was developed with the intent of improving on the strength and toughness of ferrous alloys. Ductile iron, with its relative ease of use and low cost of manufacture, has been one of the largest beneficiaries of the austempering process.

Because it can be cast like any other ductile iron, ADI offers all the production advantages of a conventional ductile iron casting. Consequently it is subjected to the austempering process to produce mechanical properties that are superior to conventional ductile iron, cast and forged aluminum and many cast and forged steels.

Carson Castings (Foundry-Source.com) represents the best austempered ductile iron foundries in the USA and backs it up with professional and ongoing service. We deal strictly in the sourcing of castings and machined castings. We can provide raw castings or complete assemblies and everything in between (painting, heat treat and machining).

Our years of experience in the casting field ensure we place your work at a facility suited to your project’s unique needs. Our tooling options include no bake and green sand molding. We also offer floor, manual, squeezer, cope and drag, Hunter, Sinto and Disa molding processes.

Some of the applications of ASTM A897 ADI Grade 1200 / 175 (Grade 3) include:

- Farm Machinery and Construction Equipment:

- Plough Points

- Hitches

- Control Arms

- Digger Teeth

- J-Hooks

- Control Arms

- Draft Arms

- Bucket Teeth

- Trencher Tools

- Heavy Truck Equipment:

- Diesel Engine Timing Gears

- Hypoid Ring and Pinion Gears

- Jack Stand Gears

- Suspension Brackets

- Gear Housings

- Sprockets

- CV Joints

- Differential Housings

- Wheel Hubs

- Gears / Power Equipment:

- Diesel Engine Timing Gears

- Hypoid Ring and Pinion Gears

- Off-Highway Drive Axles

- Ring Gears

- Gear Housings

- Sprockets

- CV Joints

- Differential Housings

- Wheel Hubs

- Miscellaneous Equipment:

- Conveyor Links

- Trolley Bodies

- Pipe Bending Components

- Tool Holders

- Rail Components

Whether you need ten ADI castings for prototypes or thousands of castings for production runs, Carson Castings can provide the right ADI foundry that offers complete and flexible services. Call us today at 419-891-2231 for a no obligation price quote.

AUSTEMPERED DUCTILE IRON SOURCE

We represent the best austempered ductile iron foundries in the USA and back it up with professional and ongoing service.

Carson Castings (Foundry-Source.com) specializes in ADI sand castings weighing 1# to 500# and up to 48”x48”

- Expertise in our field - We deal strictly in the sourcing of castings and machined castings. Highly specialized in austempered ductile iron.

- Added Value - We can provide raw castings or complete assemblies and everything in between (painting, heat treat and machining).

- Tooling Options – No-bake and green sand molding. Floor, manual, squeezer, cope and drag, Hunter, Sinto and Disa molding processes.

- Industry Knowledge - Our years of experience in the casting field ensure we place your work at a facility suited to your project’s unique needs.

Austempered Ductile Iron (ADI) has all the advantages of a ductile iron casting plus mechanical properties which are superior to all cast irons and most steel forgings and castings, thanks to a special heat treat process. Its strength, wear resistance and toughness are equal or better than steel, while it’s damping properties are five times greater than steel. In density, ADI is .26 lbs. per cubic inch compared with steel’s .28 lbs. per cubic inch. ADI offers one of the best combinations when it comes to lower costs, design flexibility, machinability and strength-to-weight ratio.

Markets that are heavy users of this technology include:

- Construction and mining equipment

- Material handling

- Ag implement and equipment

- Automotive

- Heavy Truck

- Railroad

Austempered Ductile Iron (ADI) has all the advantages of a ductile iron casting plus mechanical properties which are superior to all cast irons and most steel forgings and castings, thanks to a special heat treat process. Its strength, fatigue strength and toughness are equal or better than steel, while its damping property is five times greater than steel. In density, ADI is .26 lbs. per cubic inch compared with steel’s .28 lbs. per cubic inch. ADI offers one of the best combinations when it comes to lower costs, design flexibility, machinability and strength-to-weight ratio.