Ductile Iron Castings

We represent the best ductile iron foundries in the USA and back it up with professional and ongoing service.

Range of Volume

We offer ductile iron castings in a range of volumes. From prototype castings using 3D printed sand molds, up to production casting running in the hundreds of thousands. We likely work with a ductile iron foundry that can meet your exact needs.

Range of Sizes

We work with a wide range of foundries to insure we can provide you the exact size casting your project needs. Our ductile iron castings weight range stretches from a few ounces up to 7,500 pounds, and our max envelope size is approximately 70” x 70”.

Material Grades

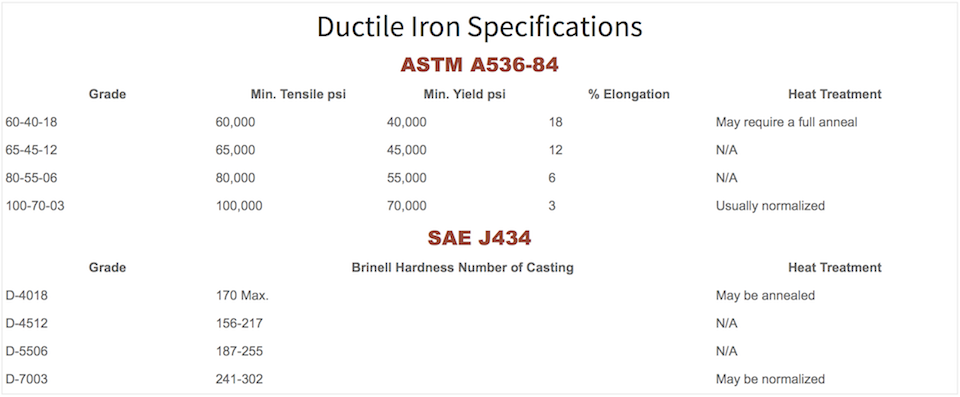

Our ductile iron castings are available in several material grades. Including ASTM A536 and SAE J434. We also supply other specialty grades including heat resistant ductile iron and abrasion resistant ductile iron grade castings.

Ductile Castings Gallery

Brake Spider 14lbs

Connection 5lbs

Piston Cover 2lbs

Shaft and Hub Assembly 9lbs

Shift Fork 1lbs

Conveyor Component 4lbs

Pillow Block 6lbs

Handle 2lbs

Link Pin 4lbs

Crankshaft 3lbs

Adjuster Collar 8lbs

Gear Housing 15lbs

Why Call Carson Castings For A Quote?

1. What Grades of ductile iron do you source?

ASTM A536 and SAE J434. We also supply special heat and wear resistant grades including ASTM A439, A436 and SAE J2582.

2. What range of sizes are available?

Weight ranges from a few ounces up to 7,500 lbs. Dimensions up to 70” x 70”.

3. What EAU can you provide?

This is weight dependent, but as a general rule we can supply up to 50,000 pieces a year in weights up to 150 pounds. From 150 pounds to 500 pounds we can service EAUs up to 2,500 pieces. 500 pounds and up 1,000 EAU.

4. What type of molding processes do you have available?

Both greensand and no-bake. Greensand includes both semi-automatic and automatic molding lines (including Sinto, Hunter, B&P and Disa molding)

5. What type of quality control procedures do you have in place?

The majority of our partner foundries are ISO Certified. We also offer x-ray, mag particle and other NDT services for projects requiring enhanced QC checks.

6. States We Serve

- Illinois

- Indiana

- Iowa

- Kansas

- Kentucky

- Michigan

- Minnesota

- Missouri

- Nebraska

- North Carolina

- Ohio

- Oklahoma

- Pennsylvania

- Virginia

- West Virginia

- Wisconsin

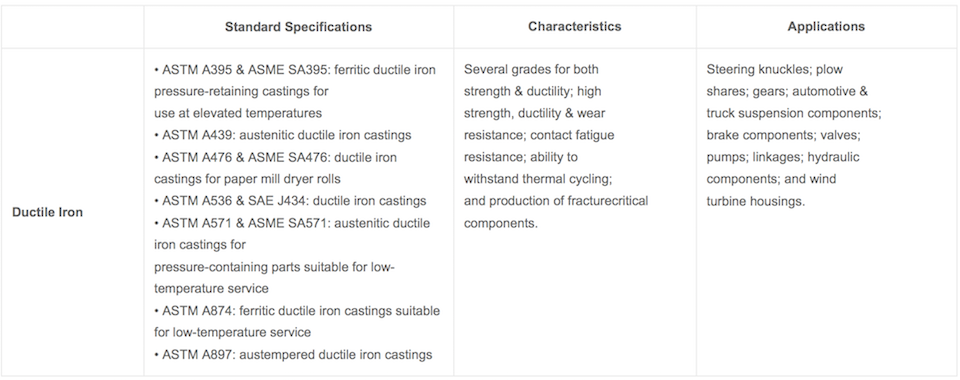

Characteristics of Ductile Iron

- 1. Ductile iron castings offer a wide range of mechanical properties:

- The ductile iron family offers the designer and engineer a unique combination of strength, wear resistance, fatigue resistance, and toughness, as well as excellent ductility characteristics.

- Tensile Strength:

- The tensile strength of ductile iron begins where gray iron stops. The as-cast tensile strength of ductile iron ranges from 60,000 to 100,000 psi

- Yield Strength:

- The yield strength of A395 ductile iron is a minimum of 40,000 psi. This is higher than grades 70-36 and 60-30 cast steel or ordinary gray iron (which has no true yield strength)

- Ductility

- Ductile iron is one of the most ductile of all cast irons and shows 18% to 30% elongation on a test piece.

- 2. Ductile iron castings are economical:

- Ductile iron castings are a cost effective substitute for carbon and low alloy steels, and in some applications, ductile iron can even outperform steel. Ductile iron is less brittle than most types of iron. Several grades can be used in the as-cast condition without additional heat treatments. When heat treated ductile iron’s design flexibility can be enhanced to an even greater degree.

- 3. Ductile iron castings outperform cast steels and gray iron in many applications:

- The improved mechanical properties of ductile iron increase its resistance to breakage from physical load, or mechanical and thermal shock far above that of gray iron. Its wear resistance is comparable to some of the best grades of steel and superior to gray iron in heavy load or impact load situations. It is considerably less expensive than cast steel and only moderately more expensive than gray iron. Its high yield strength and ductility make it an economical choice for many applications.

- 4.Ductile iron castings are readily available:

- Unlike cast steel, ductile iron capacity in North America is abundant. This ensures the end user that production lead-times are reasonable and that a variety of suppliers are capable of producing their product.

Ductile iron, a family of versatile cast irons, offers the design engineer versatility. Its mechanical properties – strength, wear resistance, fatigue strength, toughness and ductility - are competitive with many cast, forged, and fabricated steel products, yet the result, in most cases, is lower cost and better looking parts.

Ductile iron’s ease of maching and economy of production are almost equal to gray iron. The use of ductile iron has grown rapidly in the past 40 years, mainly through conversions from gray and malleable iron castings, steel castings, forgings and fabrications, and also through its use in new components designed with ductile iron.